Manufacture and sales of packaging materials for food and household goods

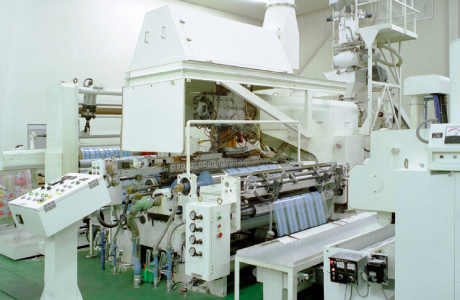

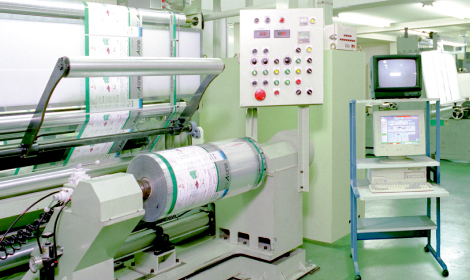

The high-speed gravure printing machine is equipped

with an automatic inspection machine that can record images of defects.

Prevent printing errors and print high quality package film.

We have installed 9 color, 8 color and 7 color high speed gravure printing machines. Printing with a small number of colors is also performed by distribution. The printing machine is equipped with an automatic defect detection device that can record images of defects such as blurs, misregistration, doctor lines, and ink loss. The introduction of this system has made it possible to prevent printing errors and enable the printing of beautiful hygienic high quality packaging films.

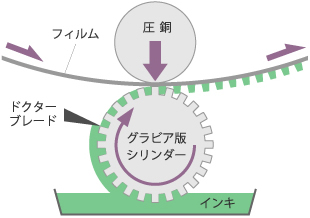

A kind of intaglio printing

Fine shading is beautifully expressed

Photo images are also printed beautifully

Food packaging film,Suitable for wood printing of furniture and home appliances, art books, photo books, etc.

The gravure plate cylinder rotates and the pumped ink is removed by doctor blade.

The ink remains in the depressions of the pattern, and is transferred to the film by the pressure of the impression cylinder, and the pattern is reproduced.

Dry lamination can be laminated from 7μ film to 0.8mm thick sheet.

PP extrusion lamination is a method in which CPP is directly extrusion laminated to OPP,

Since no adhesive is used, non-solvent runminates that use a solvent-free type adhesive with less residual solvent are introduced, enabling processing that is superior to the environment and hygiene.

These lamination machines carry out the dry lamination of wide range of films: from thin films to thick films,and also supports a wide range of PP extrusion laminates with excellent environmental health.

| Thickness | thin films of 7 μm ~ thick films of 0.8 mm |

|---|---|

| Sheet width | minimum 440 mm ~ maximum 1,200 mm |

PP Extrusion Laminating Machine (Affiliated company: EcoloLaminate Co., Ltd.)“EcoloLaminate,” is a laminating method in which OPP sheets are laminated with directly extruded CPP.Since the method does not use adhesives, the products contain very little residual solvent and therefore are friendly to the environment.In addition, EcoloLaminate products do not need aging and can be used for slitting and bag manufacturing soon after their production.The technology has enabled faster delivery and lower cost.

| Thickness | 13 μm ~ 70 μm |

|---|---|

| Sheet width | 500 mm ~ 1,200 mm |

An environmentally friendly laminating method which is urethane-based non-solvent adhesive without using an organic solvent.

| Thickness | 12 μm ~ 80 μm |

|---|---|

| Sheet width | 650 mm ~ 1,200 mm |

Nine slitters are in operation and a high-speed slit with a width of 40mm to 1500mm is performed.

| Sheet width | 440 mm ~ 1,500 mm |

|---|---|

| Slitting interval | minimum 40 mm for 14 slit sheets |

The head office factory is accredited by the Soft Packaging Sanitation Council.

In addition, inspection and quality control are conducted on all products,

and they will be shipped after strict checks.

The head office plant is accredited by the Soft Packaging Sanitation Council.

The air shower and the wearing of electric stone cap prevent the mixture of dust and hair.

In addition, the internal pressure in the factory is increased, and a factory positive pressure system is used to prevent the intrusion of dust and insects from the outside of the building.

"Soft packaging hygiene council" authorized factory

"Green printing plant" certification

Certification number:H30050

Green printing factory certificate

Laboratory

Quality management Office

Print version automatic

control rack warehouse

Gas chromatograph

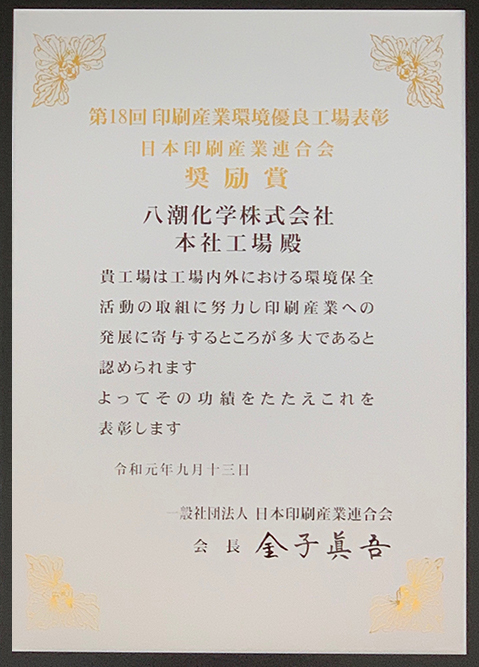

Won the 18th printing industry environmental excellence factory award

Received the Japan Printing Industry Federation Encouragement Award in the award system implemented for the purpose of acquiring environmental support in the printing industry, improving the environment of the printing factory, and gaining the support and understanding of society from printing companies.

We look forward to your feedback.

Please contact us by email, phone or fax.

TEL 0297-48-3541

FAX 0297-48-3542

TEL 03-3866-5340

FAX 03-3866-2636